| Type | NS 60 | NS 100 | NS 120-130 | NS 160-180 | |

| Plant Capacity (m³/h) | 60m³/h | 100-110m³/h | 120-130m³/h | 160 – 180 m³/h | |

| Mixer Type | SINGLE SHAFT | TWIN SHAFT | TWIN SHAFT | TWIN SHAFT | |

| 1500/1000 | 3000/2000 | 4500/3000 | 6750/4500 | ||

| Mixer Capacity | 1 m³ | 2 m³ | 3 m³ | 4,5 m³ | |

| Dry Capacity | 1500 liter | 3000 lt. | 4500 lt. | 6750 | |

| Compressed Concrete | 1000 liter | 2000 lt. | 3000 lt. | 4500 lt. | |

| Mixing Motor Power | 37 kw | 2×37 kw | 2×55 kw | 2×90 kw | |

| Aggregate Bunker Compartments | 4 | 4 | 4 | 4 | |

| Aggregate Bunker Capacity | 60-120m³ | 120-200m³ | 120-200m³ | 160-400m³ | |

| Aggregate Weighing Belt | 800 mm / 15000 mm | 1000 mm / 15000 mm | 1000 mm / 16000 mm | 1200 mm / 16000 mm | |

| Feeding Belt Conveyor | 800 mm / 28000 mm | 1000 mm / 30000 mm | 1000 mm / 33000 mm | 1200 mm / 34500 mm | |

| Aggregate Collecting Hopper | 2500 kg | 5000 kg | 5000 kg | 11000 kg | |

| Cement Weighing Hopper | 500 kg | 2000 kg | 2000 kg | 3000 kg | |

| Water Weighing Hopper | 300 kg | 1000 kg | 1000 kg | 1250 kg | |

| Additive Weighing Hopper | 50 kg | 50 kg | 50 kg | 50 kg | |

| Cement Screw | 219/7000-11500 mm | 273/7000-11500 mm | 273/7000-11500 mm | 323/12000 mm | |

| Water Pump | 25 m3/h | 50 m3/h | 50 m3/h | 2×50 m3/h | |

| Air pressure tank | 1500 lt/m | 1800 lt/m | 1880 lt/m | 2400 lt/m | |

| Total motor power | 100-125 kw | 150-185 kw | 200-220 kw | 330-355 kw | |

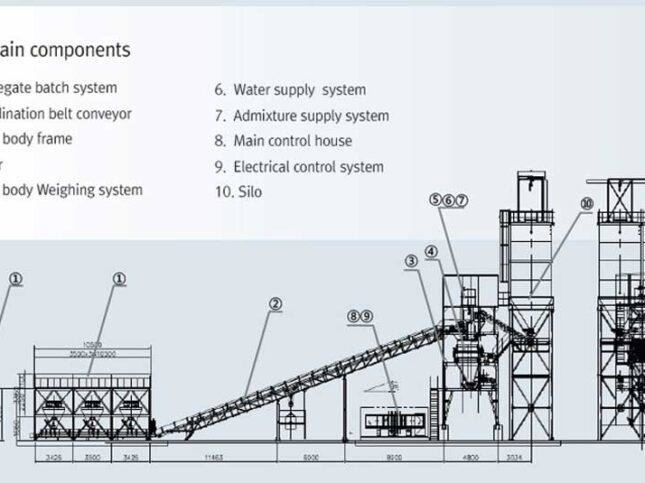

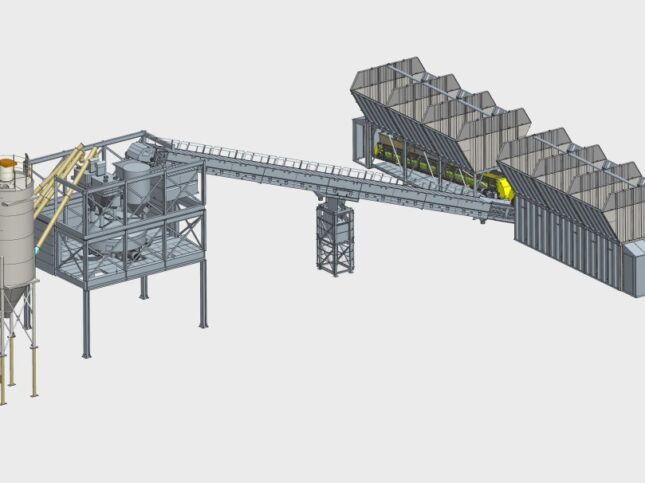

STATIONARY TYPE CONCRETE BATCHING PLANT

SETTLEMENT AND LAYOUT PLANS

STATIONARY TYPE CONCRETE BATCHING PLANT

Aggregate Bunker

Role and Importance

In every Stationary Concrete Batching Plant, the aggregate bunker plays a key role in weighing and distributing materials efficiently.

The aggregate batcher, also known as the aggregate bin, is an automated system used for weighing and distributing materials in concrete batching plants. In these systems, aggregates are typically measured by weight. Therefore, choosing the correct batching configuration is essential for achieving concrete consistency and performance.

Different grades of concrete require various types and proportions of aggregates. For example, high-strength concrete needs specific aggregate mixtures. Before investing, it is important to determine which concrete grades you plan to produce.

Moreover, accurate weighing not only guarantees consistent quality but also reduces material waste. Overall, the aggregate bunker plays a critical role in ensuring production efficiency and material precision.

Cement Silo

The cement silo in a Stationary Concrete Batching Plant helps maintain continuous operation and ensures material stability.

It mainly stores bulk cement, fly ash, mineral powder, and other materials.

Storage and Capacity Planning

Modern silos protect stored materials from moisture and contamination, thereby maintaining product quality over time. In addition, selecting the correct silo capacity ensures stable production without interruptions.

As a result, productivity increases and downtime decreases. However, choosing a silo that is too small can lead to delays and operational inefficiency. Consequently, careful planning is required when determining the appropriate silo capacity for your concrete plant.

Concrete Mixer

Core of the Batching Process

The mixer is the heart of any Stationary Concrete Batching Plant, where all raw materials are blended into uniform concrete.

Concrete mixers ensure uniform blending of aggregates, cement, and water. Generally, two major mixer types are used in concrete batching plants: planetary mixers and twin-shaft mixers.

Thus, the type of mixer directly affects production speed, energy efficiency, and final concrete quality.

Planetary Concrete Mixer

The planetary mixer is ideal for precast and low-slump concrete applications. It operates through a rotating main shaft with multiple mixing stars, ensuring thorough material circulation and preventing dead zones.

As a result, this mixer offers excellent blending performance for block-making and precast industries. Furthermore, its design improves particle bonding and prevents cement agglomeration, leading to highly uniform mixtures.

Twin-Shaft Concrete Mixer

The twin-shaft mixer is widely used in ready-mix concrete production. It features two horizontal shafts and multiple mixing blades, allowing extremely fast and efficient mixing.

In many cases, belt-fed models ranging from 1–3 cubic meters are common in medium and large batching plants. On the other hand, planetary mixers may be preferred for highly specialized precast operations.

Steps to Maintain the Plant for a long time:

*When you use, fill up the lubrication oil according to requirements, check the control equipment and circuit.

This will help the mixer to work efficiently and produce more concrete than before.

*Brake and clutch are an important element of such type of plants so, every time you need to check the reliability of them.

It takes only 5 to 10 minutes to be checked but it can save you from a big loss.

*An operator should check that the motor, transmission or reducer gear is creating abnormal noise or not.

If he hears such noise then it should be repaired first t then start the operating process. Also, check that the temperature is rising too high or not.

*Once the work is finished, an operator should clean whole mixer machine with care.

Our Concrete Batching Plant has been designed for producing high-quality concrete.

It has the advantages of large output, high efficiency, high stability and high specification, which adopts reliable and flexible components, making it easy to maintain and own a low failure rate

It is widely used in various projects such as roads and bridges, ports, tunnels, dams and buildings.

Maintenance Guide: Extend Plant Life

1. Keep the Mixer Clean

Always remove dirt and concrete residue from the mixer. This way, you protect components and ensure long-term efficiency.

2. Maintain Lubrication and Check Controls

Regularly fill lubrication oil and inspect electrical control systems. As a result, the mixer runs smoothly and maintains stable production capacity.

3. Inspect Brakes and Clutch

Brakes and clutch systems are critical for safety. Although the inspection takes only a few minutes, it prevents costly failures and downtime.

4. Listen for Unusual Noises

Operators should check motors, gearboxes, and transmission systems for abnormal sounds. If noise is detected, repair it before restarting the plant. Furthermore, monitor temperature levels to prevent overheating.

5. Clean After Each Operation

After finishing daily work, clean the mixer and surrounding equipment. In conclusion, this prevents hardened concrete build-up and improves operational lifespan.

Regular maintenance of your Stationary Concrete Batching Plant ensures longer service life and consistent concrete quality.

Stationary Concrete Batching Plant FAQ

What is a stationary concrete batching plant?

A stationary concrete batching plant is a fixed facility designed to produce large volumes of concrete. It includes a mixer, aggregate bins, cement silos, conveyors, and an automated control system.

What are the main components?

Key components include:

-

Aggregate bins

-

Weighing scales for aggregates, cement, and water

-

Mixer (twin-shaft or planetary)

-

Cement silos

-

Automated or manual control system

How does it work?

Raw materials such as aggregates, cement, and water are measured precisely. Then, they are fed into the mixer and blended according to the selected recipe. Finally, the ready concrete is discharged into mixer trucks or molds.

What are the advantages?

Higher production capacity, consistent concrete quality, flexible mix designs, and reduced maintenance costs.

What is the capacity range of a Stationary Concrete Batching Plant?

Capacities range from 30 m³/h to over 300 m³/h, depending on configuration and project needs.

Can it be customized?

Yes, batching plants can be customized with additional silos, larger mixers, dust filters, moisture sensors, and automation systems.

Which concrete types can be produced?

They can produce standard concrete, high-strength concrete, self-compacting concrete, and specialty mixes for infrastructure projects.

How long does installation take?

Installation usually takes a few weeks to several months, depending on plant size and site conditions.

What about maintenance?

Regular maintenance includes calibration of weighing systems, mixer cleaning, lubrication of moving parts, and control system checks.

How is concrete quality ensured?

Use high-quality raw materials, follow precise mix designs, and maintain equipment properly. In this way, periodic testing guarantees reliability.

Is operator training available?

Yes, most manufacturers provide training for safe and efficient operation.